Why China Matters in Stage Truss Manufacturing

China is a global powerhouse in event infrastructure manufacturing, especially for stage truss systems. Thanks to a mature supply chain for aluminum extrusion, welding, surface finishing, and quality control, Chinese truss factories are able to produce a wide variety of truss types — from lightweight DJ square truss to heavy-duty concert roof truss — at competitive prices and scalable volumes.

Over the past decade, demand for high-quality trussing has skyrocketed in live concerts, corporate events, trade shows, and weddings. As production scales, buyers increasingly require reliable safety certifications, such as TÜV or CE, plus documented load-bearing capacities. Meanwhile, Chinese manufacturers have responded by upgrading their R&D, adopting CNC machinery, employing experienced welders, and offering full engineering support to global customers.

Given this dynamic, knowing how to evaluate truss manufacturers is not just about price — it's about engineering integrity, quality assurance, delivery, and long-term support.

How to Choose a Stage Truss Manufacturer: Key Evaluation Criteria

When sourcing stage truss, here are the critical dimensions to evaluate:

Material Quality.

High-grade aluminum(e.g., 6082-T6) ensures strength-to weight ratio. Confirm the alloy, temper, and source.

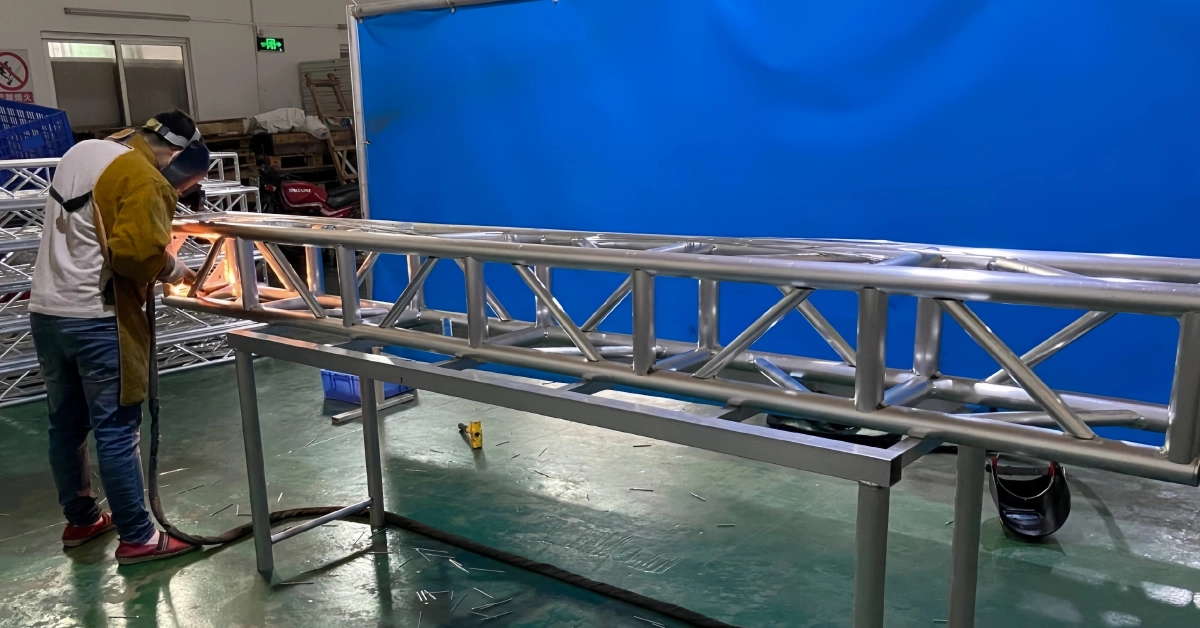

Manufacturing Craftsmanship

Welding quality: look for certifications, consistent welds, no cracks.

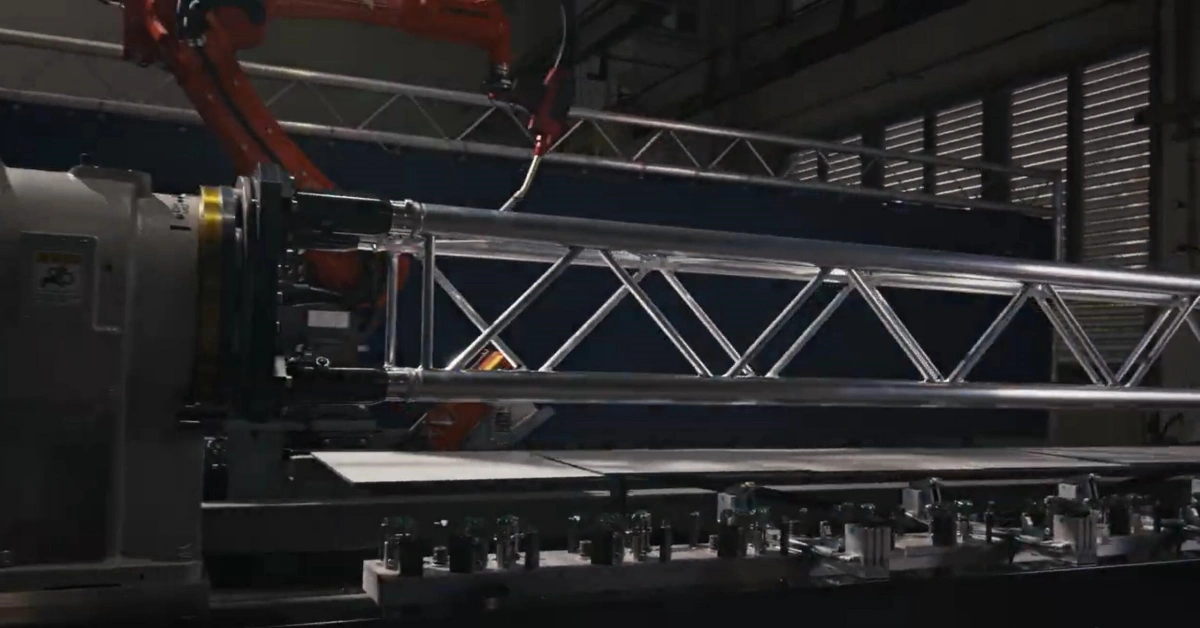

CNC machining: ensures precision on connectors, spigots, and panels.

Structural Engineering & Load Testing

The supplier should provide load tables, engineering calculations, and ideally third-party testing(TUV, SGS, etc.)

Design Flexibility

Abilit to supply CAD drawings, custom spans, special-shaped truss, or roof systems.

Certifications & Compliance

CE, ISO, EN-1090, TUV are strong indicators of quality and safety.

Capacity & Lead Time

Factory size, production throughput, stock availability, and avility to handle urgent or large orders.

After-Sales & Spare Parts

Availabilit of spare parts, accessories, and compatibility of componets across orders.

Case Experience

Real projects(concerts, weddings, exhibitions)demonstrate practical capability and reliability.

Packing and Shipping

How trusses are packed (flight caes, reinforced packaging), and the manufacturer's experiecne in global logistics.

Pricing & Trade Terms

Transparent costing (EXW, FOB, CIF), MOQ ,payment terms, and willingness to negotiate.

Leading Stage Truss Manufacturers in China (≈ 50+ Examples)

1. Skymear Stage Truss

2. Guangzhou Chaoda Performance Equipment Factory

3. WTC (Guangzhou ZhiGou Truss Co., Ltd.)

4. Jiayi Truss (Foshan Jiayi Technology Co., Ltd.)

5. Guangdong Hengxin Metal Structure Co., Ltd.

6. Guangzhou Young Stage Equipment Co., Ltd.

7. LEDIKA Flight Case & Stage Truss Co., Ltd.

8. Guangzhou Juchen Stage Equipment Co., Ltd.

9. Bravostage (Guangzhou).

10. Guangzhou YaoNa Stage Technology Co., Ltd.

11. Foshan Hongzi Performance Equipment Co., Ltd.

12. Guangzhou Xingyue Performance Equipment Co., Ltd.

13. Guangzhou Huawei Performance Equipment Co., Ltd.

14. Guangzhou Smart Truss / Smart Structure

15. Jiangsu Shiz Group / Shiz Truss

16. Guangzhou Dragon Performance Equipment Co., Ltd.

17. Guangzhou Kenzo Performance Equipment Co., Ltd.

18. Guangzhou MingXuan Stage Light Equipment Co., Ltd.

19. Guangzhou Sgaier Truss Co., Ltd.

20. Guangzhou PinYuan Performance Equipment Co., Ltd.

21. Guangzhou Bravo Stage Equipment Co., Ltd.

22. Beijing Zhongzhan Shengbo Exhibition Stage & Truss Factory

23. Wuxi Senke Metal Products Co., Ltd.

24. Guangzhou Eagle Truss / Eagle Stage Equipment

25. Guangzhou TOPTRUSS

26. Guangzhou MingDao (GTD) Performance Equipment

27. Guangzhou PinYuanQiCai

28. Guangzhou Shenglianxin

29. Guangzhou BingHui

30. ICTC / ICTC-Huawei (Guangzhou)

31. Guangzhou Eagle Group / Eagle Stage Guangzhou Juyong Stage Equipment Co., Ltd.

32. Guangzhou SGAIER Performance Equipment

33. Shenzhen TourGo Event Solution Co., Ltd.

34. Guangzhou Xingfa Performance Equipment.

35. Guangzhou Jincheng Metalwork Co., Ltd.

36. Guangzhou SGAIER Truss.

37. Guangzhou Golden Sea / Golden Sea Professional Equipment.

38. Guangzhou Smart Stage Structures.

39. Guangzhou TAF-Backed Truss Manufacturer.

40. Guangzhou PinYuanQicai Truss Co.

41. Guangzhou Shengyi Xin Truss.

42. Guangzhou YaoNa / YaoNa Stage.

43. Guangzhou Kenzo Performance.

44. Guangzhou StarLeap Performance Equipment.

45. Guangzhou Huawei Stage Equipment.

46. Guangzhou MingXuan Stage Light Equipment.

47. Guangzhou Dragon Stage / Dragon Truss.

48. Guangzhou Young Stage Equipment.

Why Choose InfiTruss — Key Differentiators

Here are the main strengths of InfiTruss (Infinity Truss & Stage Co., Ltd.) and why it's a compelling choice for buyers who care about quality, safety, and service.

1. Safety-First Engineering & Third-Party Testing

InfiTruss emphasizes structural safety: its designs go through rigorous third-party load testing, including TUV or equivalent engineering calcuations, ensuring each truss component can carry expected loads reliably.

2. High-Quality Materials & Precise Craftsmanship

InfiTruss uses high-grade aluminum alloys, precision CNC machining, and skilled welders. This guarantees consistent connections, accurate tolerances, and long-term durability.

3. Comprehensive Certifications.

The company supports complicance with international standards-including ISO quality management, CE marking, and potentially TUV certifications-offering peace of mind to global clients.

4. Custom Design & Engineering Support

InfiTruss provides bespoke engineering: from 3D CAD renderings, structural calculation, to installation drawings. This flexibility enables customized stage structures, roof systems, and event-specific setups.

5. Strong After-Sales and Spare Parts

Being a factory with long-term parts inventory, InfiTruss supports customers with spare connectors, replacement beams, flight-case packaging, and maintenance advice — reducing total lifecycle cost.

6. Fast, Factory-Direct Delivery

As a manufacturer, InfiTruss can offer factory-direct pricing, transparent lead times, and potentially better stock management, ensuring quicker turnaround and better value.

7. Global Export Experience

With experience exporting to multiple regions, InfiTruss understands international shipping, customs, and packaging challenges. They can provide reinforced packing, flight cases, and support global deployment.

8. Proven Project References

InfiTruss has delivered truss systems for a variety of clients: corporate events, concerts, trade shows, and weddings. These reference projects help prospective buyers validate reliability.

9. Customer-Centric Philosophy

The company positions itself with “innovation, safety, and service” at its core. This means they prioritize responsive design support, rigorous quality checks, and long-term partnerships.

Comparison: InfiTruss vs Other Chinese Manufacturers

| Criteria | InfiTruss | Other Chinese Truss Manufacturers |

|---|---|---|

| Safety Testing | Full third-party load testing (e.g., TÜV) | Varies — not all provide independent test reports |

| Design & Customization | High: CAD, structure design, engineering support | Many offer design, but support sophistication varies |

| Material & Quality | High-grade alloys, precise machining | Quality varies widely between factories |

| Certifications | ISO, CE, possibly TÜV | Many have ISO/CE, fewer have advanced testing or safety marks |

| Lead Time & Delivery | Factory-direct, well-managed | Depends on manufacturer; some have long lead times |

| After-Sales / Parts | Strong parts support | Varies; some trade companies lack spare inventory |

| Export Experience | Experienced in global shipping | Many export, but shipping experience differs |

| Project Portfolio | Diverse, credible projects | Depends on company scale; some only small-scale |

Risks to Watch Out for When Sourcing Truss in China

1. Overly cheap quotes: Beware of unrealistic low prices; may indicate lower-grade material or poor welding.

2. Lack of test reports: Always request engineering documents or load test certificates.

3. Misleading certifications: Verify whether "CE" or "ISO" certificates are genuine and relevant.

4. Poor packaging: Truss that is not properly packed can be damaged in transit.

5. Non-standard connectors: Ensure connectors (spigot, bolts) match your existing inventory or specs.

6. After-sales challenges: Ask about spare parts, replacement beams, and long-term availability.

7. Communication risk: Language, lead time misunderstandings – choose a partner with clear communication and a good track record.

How to Onboard InfiTruss (or Any Manufacturer) Safely

1. Request Detailed Quotation

Include cross-sections, connector types, lengths, finish, and quantity.

2. Ask for Load Tables & Engineering Documents

Inquire about test reports, structural analysis, and CAD drawings.

3. Factory Audit

If possible, conduct a virtual or in-person audit: check welding, extrusion, QC, and packaging.

4. Order a Sample or Prototype

Build a small truss mock-up or demo to test integration, fit, and finish.

5. Agree on Trade Terms

Negotiate FOB, CIF or DDP. Clarify payment terms, MOQ, and delivery schedule.

6. Packing & Logistics

Confirm how the truss will be packed (flight case / wooden crate) and shipped.

7. Spare Parts Plan

Set up a spare parts order or plan so you have connectors, pins and beams on hand.

8. After-Sales Commitment

Sign a contract or agreement on after-sales support, warranty, and parts replacement.

Choosing the right stage truss manufacturer

Choosing the right stage truss manufacturer is a vital decision that affects safety, cost, and event success. While China offers a rich ecosystem of over 50+ capable and certified truss manufacturers, InfiTruss stands out due to its rigorous engineering, top-tier materials, third-party load testing, and global service experience.

If you're ready to elevate your event infrastructure with reliable, high-quality truss systems, consider contacting InfiTruss for a detailed proposal. Ask for their engineering package, case studies, and sample units. At the same time, use the list of other leading Chinese manufacturers above to benchmark and compare options.

The content above is provided by Infitruss for informational purposes. Unauthorized reproduction is prohibited. See our full disclaimer here