In the global event industry, stage truss systems are often judged by their appearance on-site—but their true value is determined long before installation begins. Behind every reliable stage structure lies a manufacturing process that combines engineering discipline, skilled craftsmanship, and strict quality control. For professional event organizers, rental companies, and distributors, understanding how a stage truss is manufactured is essential to understanding its safety, durability, and long-term performance.

This article takes you inside a professional stage truss manufacturing factory, explaining how raw materials are transformed into certified structural systems trusted by events worldwide.

The Role of Manufacturing in Stage Truss Reliability

A stage truss is not a decorative product—it is a load-bearing structural system. Its performance depends on precision at every manufacturing stage, from material selection to final inspection. Poor manufacturing practices can lead to misalignment, inconsistent load capacity, premature fatigue, and safety risks that only appear after repeated use.

Professional truss manufacturing focuses on three core objectives:

-

Structural consistency across batches

-

Predictable load performance

-

Long service life under repeated assembly and transport

Factories that lack engineering control may produce visually acceptable trusses, but they often fail to deliver long-term reliability. This is why experienced buyers increasingly evaluate the factory itself—not just the finished product.

Raw Material Selection: The Foundation of Structural Integrity

Manufacturing quality begins with material choice. Professional stage truss systems typically use high-grade aluminum alloy 6082-T6, selected for its excellent balance of strength, corrosion resistance, and weldability.

Unlike lower-grade aluminum or mixed alloys, 6082-T6 provides:

-

High tensile strength for long spans

-

Stable mechanical performance after welding

-

Strong resistance to deformation under dynamic loads

-

Long-term durability for outdoor and touring applications

In a professional factory, each aluminum batch is inspected before production. Material certificates, alloy composition, and dimensional tolerances are verified to ensure consistency. This step prevents hidden weaknesses that could compromise structural performance later.

Engineering-Driven Production: From Design to Fabrication

Modern truss manufacturing is engineering-led, not trial-and-error based. Every product begins with CAD-based structural design, where load paths, connection points, and stress distribution are calculated before any cutting or welding occurs.

This engineering phase allows manufacturers to:

-

Optimize tube diameters and wall thickness

-

Ensure compatibility across modular components

-

Predict deflection under real-world loads

-

Reduce on-site adjustments during installation

Once design parameters are finalized, production moves to CNC-controlled fabrication.

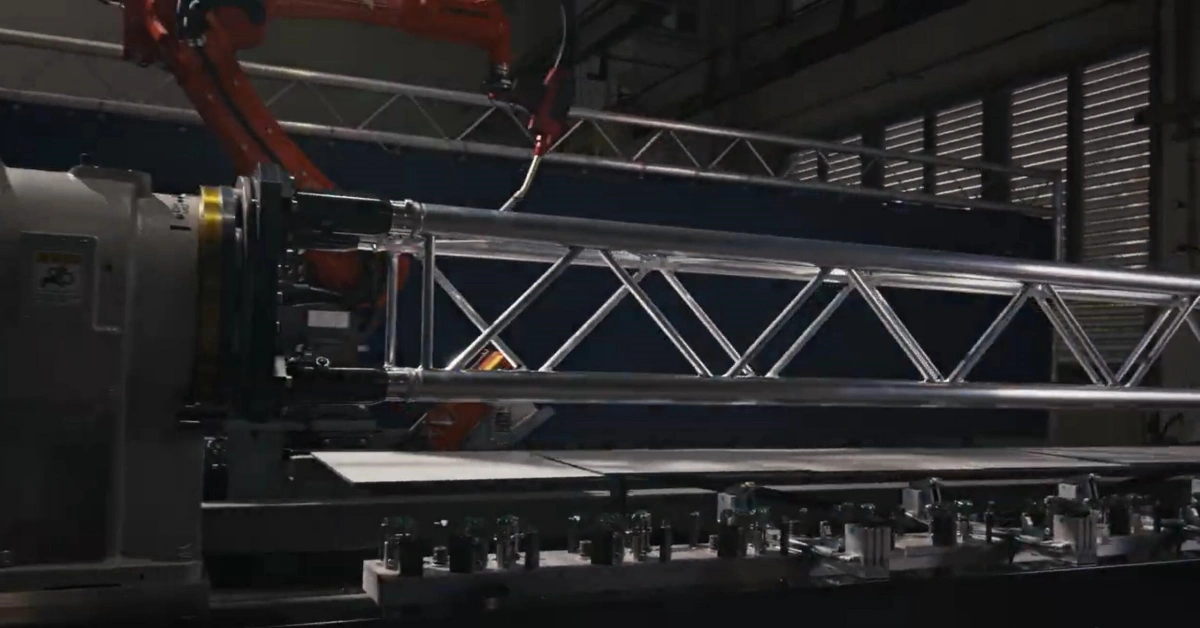

CNC Cutting: Precision That Ensures Compatibility

CNC cutting machines play a critical role in achieving dimensional accuracy. Each tube, brace, and connector is cut according to digital specifications, ensuring:

-

Exact length tolerance

-

Accurate angle alignment

-

Consistent fit across modular systems

This precision is essential for spigot and bolt connection systems, where even minor deviations can lead to assembly difficulty or uneven load transfer. CNC cutting ensures that truss sections from different production batches remain fully compatible—an important factor for expanding systems over time.

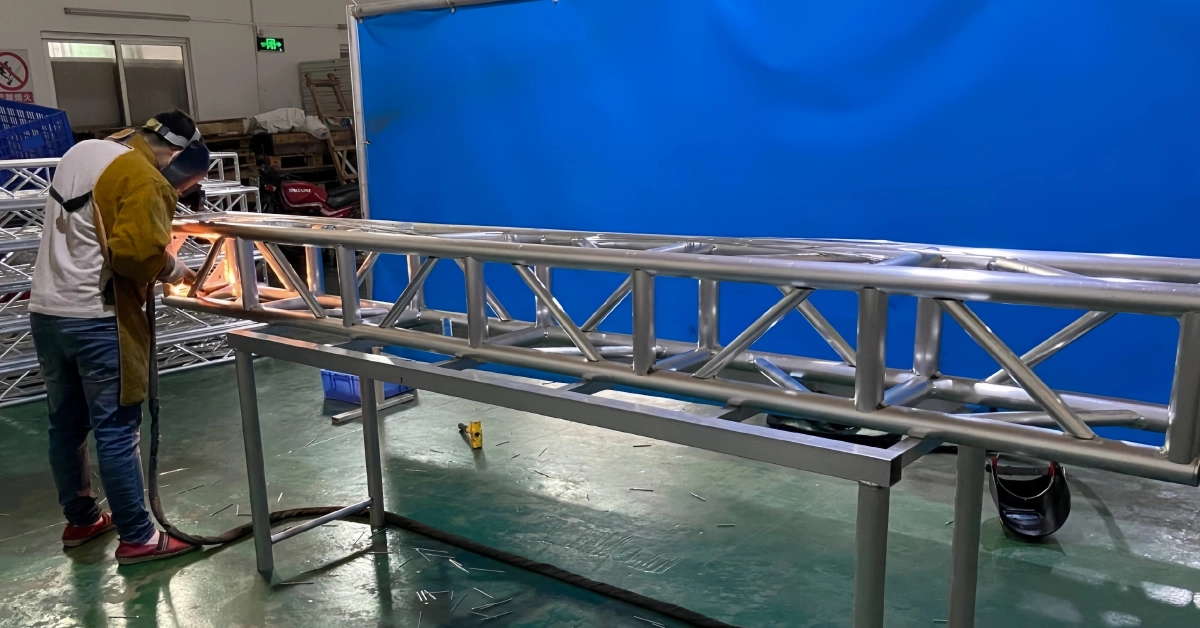

TIG Welding: Where Craftsmanship Meets Engineering

Welding is one of the most critical stages in truss manufacturing. Professional factories rely on TIG welding, performed by experienced welders trained in aluminum structural welding standards.

High-quality TIG welding ensures:

-

Deep weld penetration without overheating

-

Uniform bead appearance and strength

-

Minimal distortion of aluminum tubes

-

Reliable performance under repeated load cycles

Each weld joint is not only visually inspected but also evaluated for structural consistency. In professional manufacturing environments, welding jigs are used to maintain precise geometry during assembly, preventing cumulative misalignment.

Surface Finishing: Protection and Performance

Surface treatment is not just about appearance—it directly affects durability. Professional stage truss factories apply finishes such as:

-

Polishing for smooth handling and reduced abrasion

-

Anodizing for corrosion resistance

-

Powder coating for custom color requirements

Proper surface finishing protects aluminum from oxidation, reduces wear during transport, and improves long-term usability—especially for rental and touring systems.

Quality Control and Load Testing

True manufacturing excellence is defined by quality control, not output volume. Professional factories implement multi-stage inspection processes, including:

-

Dimensional verification during production

-

Visual and structural weld inspection

-

Connection alignment checks

-

Static and dynamic load testing

Load testing simulates real-world conditions, confirming that truss systems meet or exceed rated capacities. Certification from recognized third-party organizations, such as TÜV, provides independent validation of safety and performance.

OEM & ODM Manufacturing Capabilities

Modern truss factories are not limited to standard products. OEM and ODM manufacturing allow clients to:

-

Customize dimensions and configurations

-

Apply private branding

-

Develop application-specific solutions

-

Adapt systems for regional standards

This flexibility enables event companies and distributors to differentiate themselves while maintaining structural reliability.

Production Capacity and Consistency

A professional factory balances capacity with consistency. High monthly output means little if quality varies between batches. Mature manufacturing operations focus on repeatability, ensuring that every truss system—regardless of order size—meets the same engineering and quality benchmarks.

This consistency is critical for large-scale events, touring productions, and long-term partnerships.

Manufacturing as a Competitive Advantage

In the event industry, manufacturing quality directly impacts project success. Reliable truss systems reduce installation time, minimize risk, and support complex designs with confidence. For buyers, choosing a manufacturer with proven engineering and production discipline is an investment in safety, efficiency, and brand reputation.

A professional stage truss factory is not just a supplier—it is a structural partner behind every successful event.

The content above is provided by Infitruss for informational purposes. Unauthorized reproduction is prohibited. See our full disclaimer here