In the world of stage truss manufacturing, precision, efficiency, and consistency are key to producing high-quality products. One technological advancement that has greatly improved these aspects in recent years is the use of semi-automated welding jigs. In this blog, we’ll explore how semi-automated welding jigs are revolutionizing stage truss production and why partnering with Infitruss is the best decision for your business.

What Are Semi-Automated Welding Jigs?

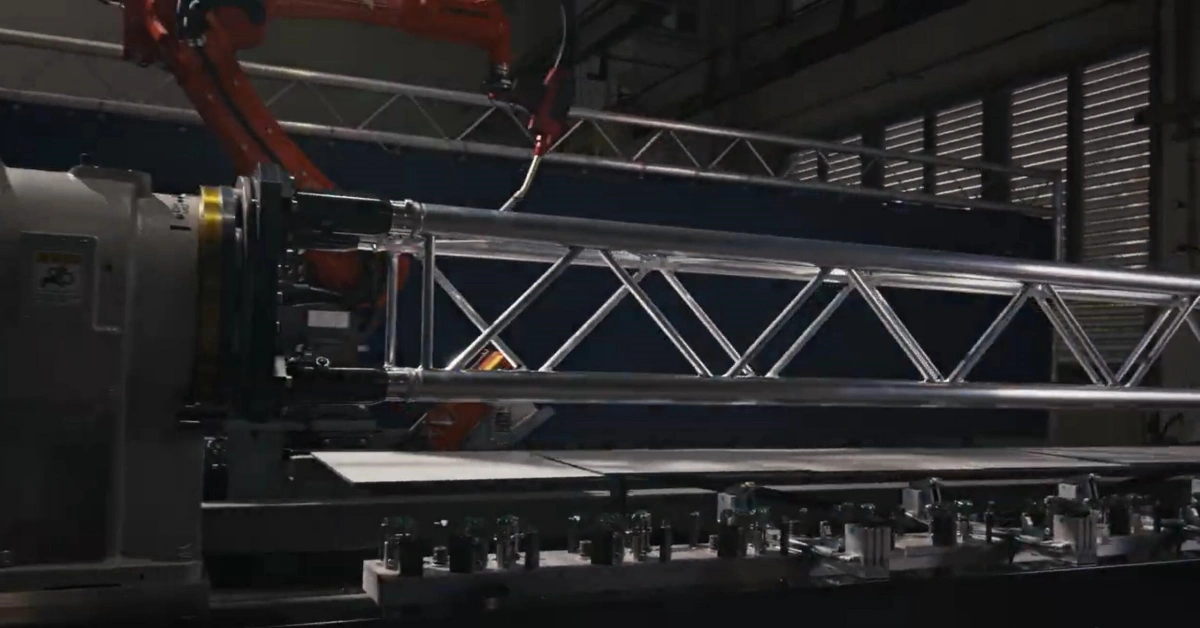

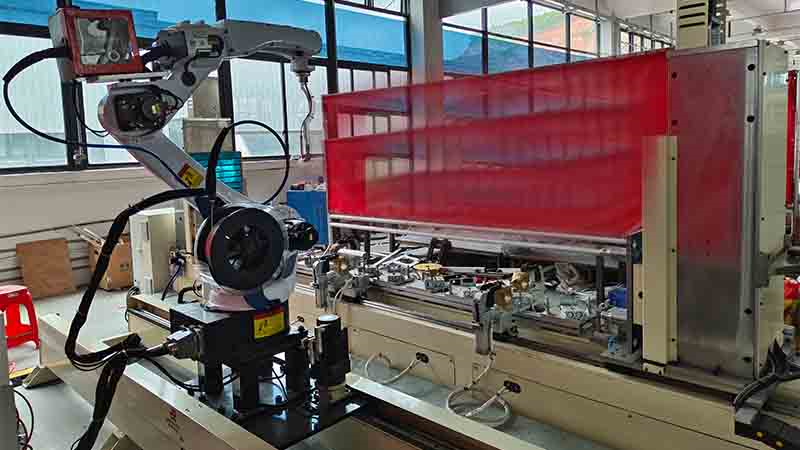

Semi-automated welding jigs are custom-built devices that assist in the welding process by securely holding, aligning, and sometimes positioning parts during welding. Unlike fully manual welding, which relies entirely on the welder’s skill, semi-automated jigs combine human oversight with automated functions like positioning and part rotation, improving overall welding precision and efficiency.

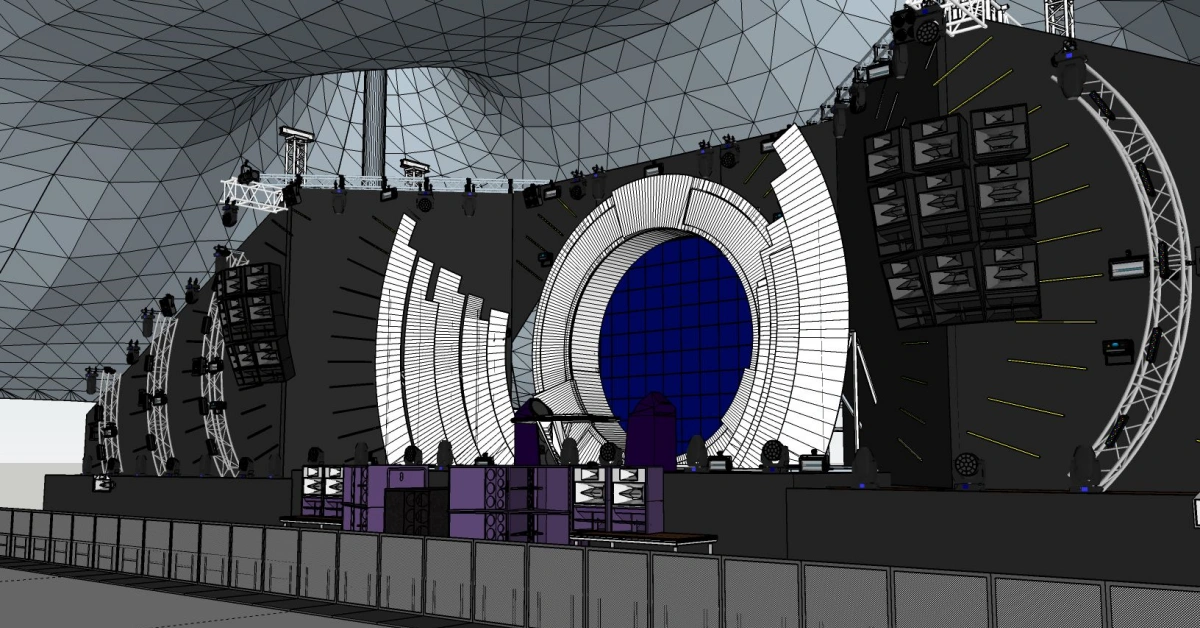

For stage trusses, which require high precision and strength to support lighting, sound systems, and other heavy equipment, semi-automated welding jigs are particularly beneficial. These jigs ensure that each truss section is welded in perfect alignment, guaranteeing strength, safety, and long-lasting durability.

Advantages of Semi-Automated Welding Jigs in Production

1. Enhanced Precision and Consistency

One of the main benefits of semi-automated welding jigs is the precise alignment they offer. When manufacturing stage trusses, the accuracy of each weld is crucial to ensure the structural integrity of the truss. With semi-automated jigs, the workpiece is positioned exactly where it needs to be, reducing the chance of errors or misalignments that could compromise the final product.

2. Improved Welding Speed

Semi-automated systems help welders focus on the welding itself, as the jigs automate the repetitive task of part positioning. This results in faster production times, enabling the factory to produce more trusses within the same timeframe. In the fast-paced event industry, this speed can be a major advantage, especially when dealing with tight timelines for large-scale events.

3. Consistent Quality Control

With manual welding, there’s always a chance for inconsistency, as human factors like fatigue or inexperience can affect the weld quality. Semi-automated welding jigs, however, ensure that every part is consistently positioned for each weld, leading to uniformity in every truss produced. This results in a higher-quality product that meets safety standards.

4. Reduced Labor Costs

Semi-automation doesn’t mean completely replacing skilled workers but rather enhancing their efficiency. By automating the repetitive tasks, welders can focus on more complex aspects of the job, reducing the need for additional labor or overtime. Over time, this can lead to cost savings for manufacturers while still producing high-quality products.

5. Flexibility for Custom Designs

Stage trusses are not a one-size-fits-all product. In many cases, custom designs are needed to fit the specific requirements of events or clients. Semi-automated welding jigs are customizable to fit different shapes, sizes, and configurations of trusses. This flexibility allows Infitruss to offer tailored solutions that meet the unique needs of every event or performance.

Why Choose InfiTruss as Your Partner for Stage Truss Production?

At InfiTruss, we understand that every detail counts when it comes to manufacturing stage trusses. That’s why we’ve invested in state-of-the-art semi-automated welding jigs to ensure that every truss is produced with the highest level of precision and efficiency.

Here’s why partnering with InfiTruss is the best choice for your stage truss needs:

1. Advanced Manufacturing Technology

InfiTruss uses cutting-edge CNC machines and semi-automated welding jigs to ensure every truss is fabricated to perfection. Our technology ensures that the manufacturing process is efficient, accurate, and meets all industry standards.

2. Customization to Meet Your Needs

Whether you need a standard truss system or a custom solution for a unique event, Infitruss has the capability to design and manufacture stage trusses tailored to your specific requirements. We work closely with you to ensure that the final product meets your exact specifications.

3. Expert Team of Engineers

Our team consists of experienced engineers and welders who are skilled in using semi-automated systems. This expertise ensures that your trusses are welded with precision and meet the highest safety standards, ensuring a reliable product for any event.

4. Fast Turnaround Time

Thanks to our semi-automated systems, Infitruss can provide quick turnaround times on large orders. Whether you need a small batch of custom trusses or a large order for a major event, we can meet tight deadlines without compromising on quality.

5. Global Reach

InfiTruss has exported stage trusses to over 40 countries around the world, including the U.S., U.K., Malaysia, and more. No matter where your events are taking place, we can deliver your trusses on time and to specification.

6. Competitive Pricing

With our efficient manufacturing process and direct factory sales model, Infitruss offers competitive pricing without compromising on quality. This means that you get high-performance stage trusses at the best possible price, ensuring great value for your investment.

Why Infitruss is Your Best Choice for Stage Trusses

Semi-automated welding jigs play a vital role in ensuring the precision, speed, and consistency needed for high-quality stage trusses. By combining cutting-edge technology with skilled craftsmanship, Infitruss is able to deliver top-tier, customizable trusses that meet the demands of any event. Whether you're organizing a concert, festival, or wedding, our stage trusses will support your lighting, sound systems, and other event setups securely and reliably.

Partnering with InfiTruss guarantees that you’re choosing a manufacturer that prioritizes quality, efficiency, and customer satisfaction. Let us help you create the perfect stage setup with our advanced trusses, manufactured using semi-automated welding jigs for superior performance.

The content above is provided by Infitruss for informational purposes. Unauthorized reproduction is prohibited. See our full disclaimer here