In the world of live events, exhibitions, and performances, stage truss safety is more than a technical requirement—it’s the foundation of trust between organizers, performers, and audiences. At Infinity Truss & Stage Co., Limited, we believe that every structure should not only inspire creativity but also guarantee the highest level of stability and reliability. From TÜV-certified materials to precise installation procedures, safety is built into every step of our truss production and deployment.

Why Stage Truss Safety Matters

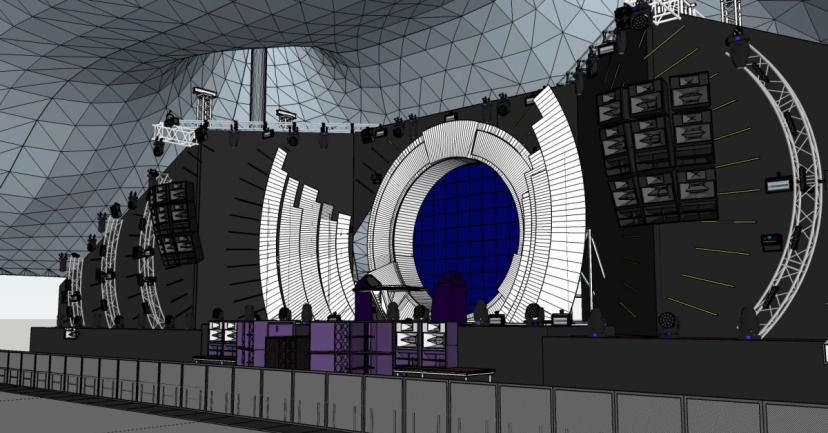

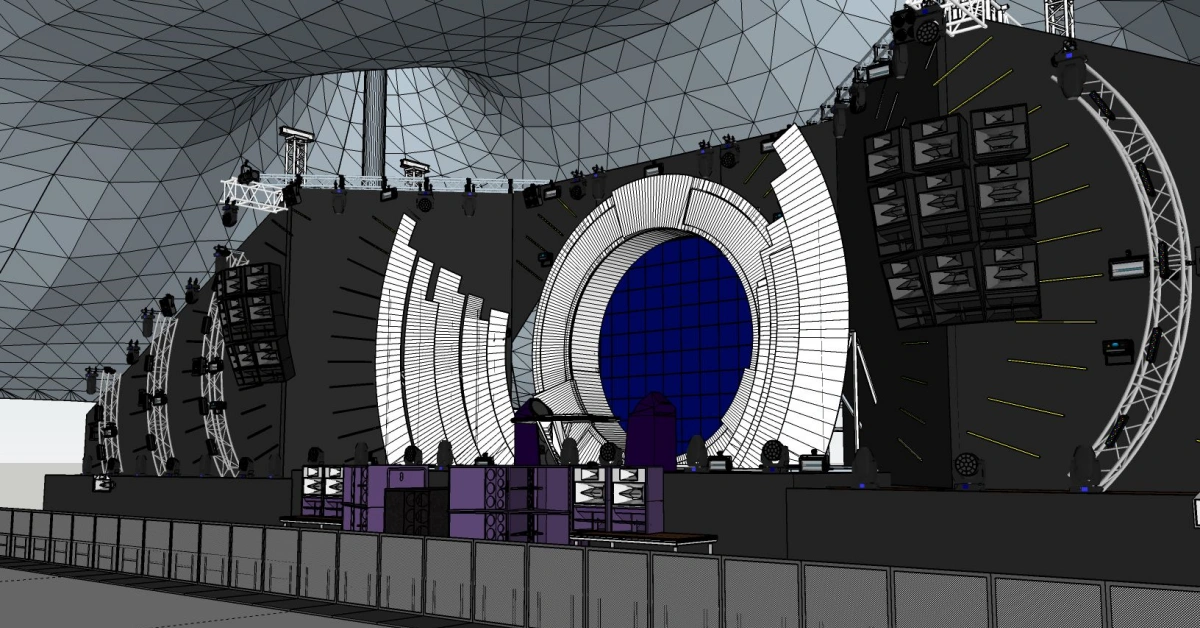

Stage truss systems serve as the backbone of every professional event—supporting lighting rigs, sound systems, LED walls, and more. Yet, beneath the visual spectacle lies a complex network of engineering that must perform flawlessly under extreme conditions.

Accidents caused by improper installation or low-quality materials can result in equipment damage, performance interruptions, or even injury. This is why following global truss safety standards is non-negotiable. Infinity Truss ensures every aluminum truss undergoes strict load testing and structural analysis before shipment, giving clients confidence to focus on performance rather than risk.

TÜV Certification and Quality Control

TÜV-Certified Engineering

Our commitment to safety begins with internationally recognized certifications. All Infinity Truss products are TÜV certified, meeting the highest European safety and performance standards.

This certification ensures that each truss meets rigorous criteria for load capacity, weld integrity, and material consistency—particularly for aluminum alloy 6082-T6, known for its excellent strength-to-weight ratio and corrosion resistance.

Quality Inspection Protocols

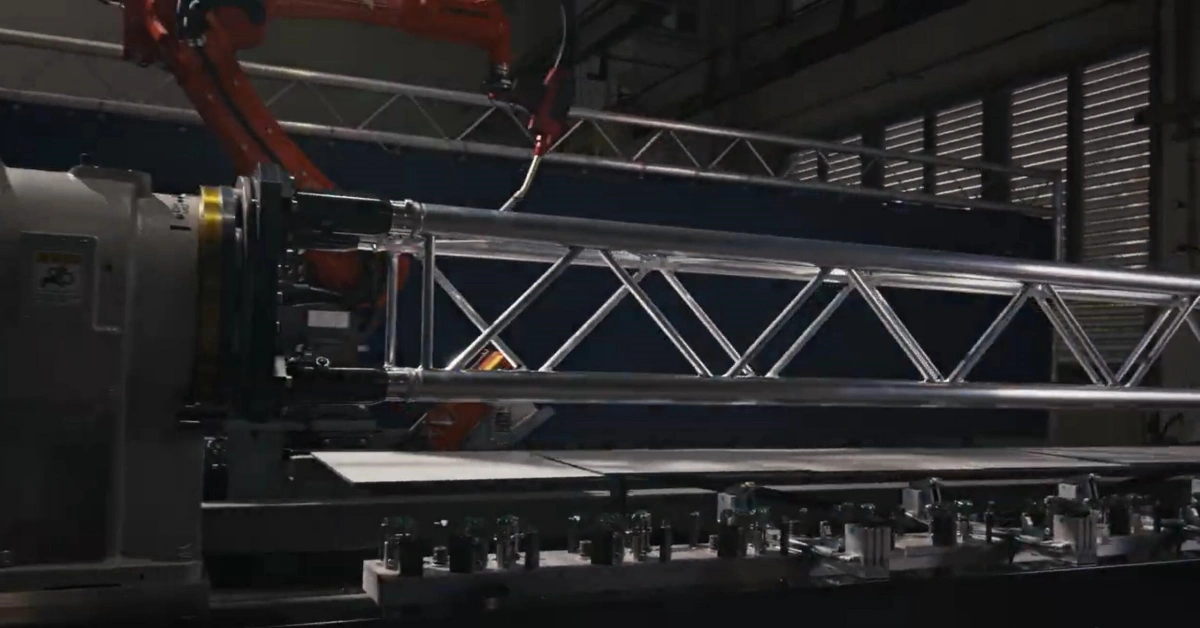

Every stage truss leaving our factory passes through multi-step inspections:

-

Material testing: verifying aluminum composition and tensile strength.

-

CNC precision cutting: guaranteeing dimensional accuracy within ±0.1 mm.

-

TIG welding review: ensuring consistent weld penetration and uniform stress distribution.

-

Load testing: confirming structural stability under simulated real-world conditions.

Through these processes, we maintain a record of every truss system’s safety performance—forming a traceable quality assurance chain.

Installation Guidelines: Building Safety On-Site

Even the most durable truss can fail if installed incorrectly. Infinity Truss provides professional installation guidelines and training support to ensure every system is assembled safely and efficiently.

Key principles include:

-

Qualified personnel only: Stage truss assembly must be conducted by trained riggers familiar with the system’s technical specifications.

-

Proper load distribution: Always align weight centers and secure diagonal bracing to prevent imbalance.

-

Connection inspection: Regularly check all spigot and bolt connections for tightness and alignment.

-

Environmental awareness: Account for wind loads, uneven terrain, or moisture exposure in outdoor setups.

Our field engineers often assist clients during installation, offering on-site supervision and post-assembly inspection—part of our after-sales commitment to safety excellence.

Structural Standards and Testing Innovations

Infinity Truss continuously improves its manufacturing process through advanced CNC technology and digital stress modeling. Each product design is validated using:

-

Finite Element Analysis (FEA): Simulating force distribution under different configurations.

-

Dynamic testing: Measuring truss vibration behavior under load changes.

-

Environmental resistance tests: Evaluating corrosion and fatigue under long-term exposure.

These innovations allow us to exceed standard requirements, making our trusses ideal for concert trusses, roof truss systems, and DJ stage setups—environments where dynamic forces are common.

Building Trust Through Compliance and Transparency

Safety is not just a product specification—it’s a promise. Infinity Truss partners with international inspectors and event engineers to ensure compliance across diverse regions.

We provide full documentation packages for every order, including:

-

TÜV certification reports

-

Load test charts

-

Assembly manuals

-

Maintenance schedules

This transparency ensures event planners, rental companies, and distributors can operate with total assurance of quality and reliability.

Continuous Education and Future Standards

As event production evolves, so do the standards for safety. Infinity Truss invests in training programs, factory tours, and knowledge-sharing workshops that educate customers on emerging technologies and installation best practices.

Our mission is to help clients understand not just how to use truss safely—but how to design, maintain, and innovate responsibly.

From sustainable material selection to AI-assisted inspection systems, the future of stage truss safety will blend technology with human expertise, and Infinity Truss is proud to lead that transformation.

The content above is provided by Infitruss for informational purposes. Unauthorized reproduction is prohibited. See our full disclaimer here