Behind every world-class event structure lies a foundation of engineering excellence, precision craftsmanship, and strict quality control. At Infinity Truss & Stage Co., Limited, manufacturing is not just about production — it’s about perfection. From aluminum cutting to final load testing, every process reflects our mission: to deliver reliable, safe, and innovative truss systems trusted by professionals worldwide.

The Heart of Our Factory: Advanced Production Technology

Located in Foshan, China, near Guangzhou’s industrial hub, our factory is equipped with state-of-the-art machinery designed to meet global truss manufacturing standards.

Every stage truss, lighting frame, and roof system starts with high-grade aluminum alloy 6082-T6, known for its superior strength, corrosion resistance, and weldability.

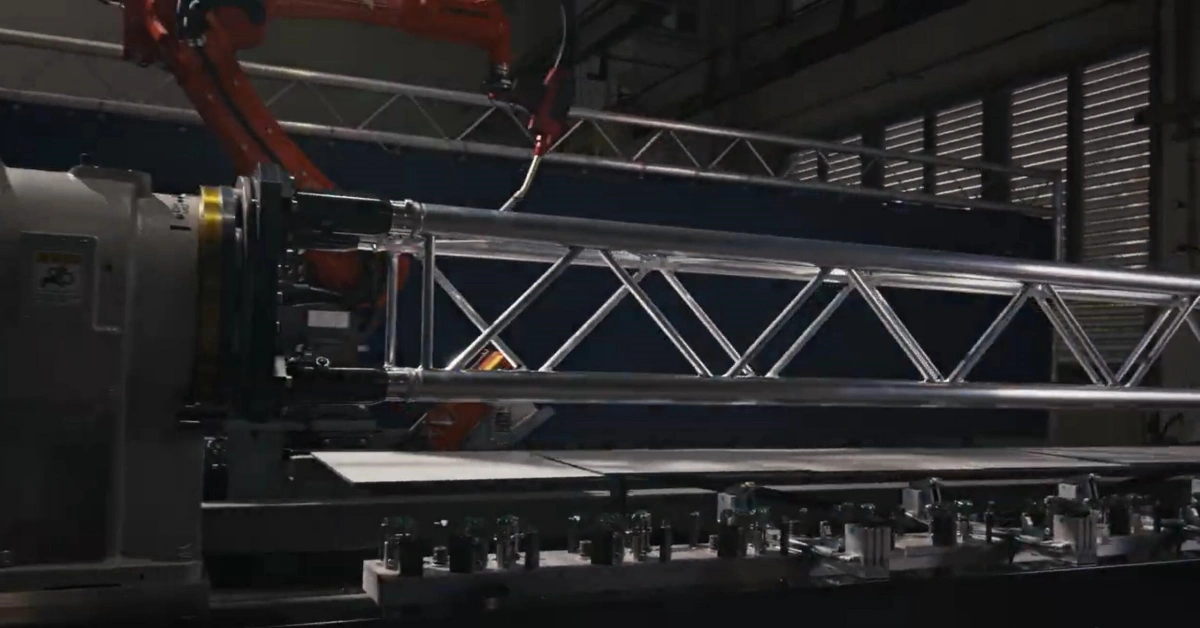

Our Key Manufacturing Technologies:

-

CNC Cutting Machines – Ensure precise dimensions with ±0.1mm tolerance.

-

TIG Welding Stations – Operated by certified welders with 10+ years of experience.

-

Automatic Polishing Lines – Deliver mirror-smooth finishes that enhance aesthetics and protect against corrosion.

-

3D CAD Design Integration – Guarantees that every project moves seamlessly from blueprint to production.

Each component undergoes digital modeling and structural simulation before entering the physical manufacturing phase, ensuring performance consistency even in the most demanding applications such as concert trusses or roof truss systems.

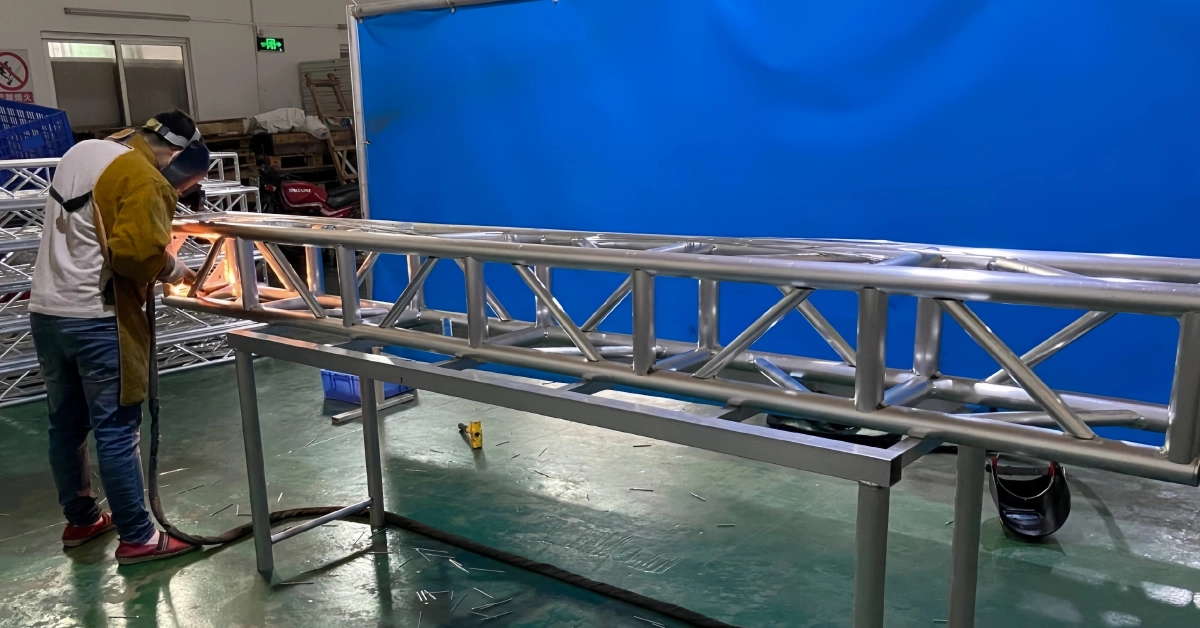

Skilled Craftsmanship: The Human Element of Manufacturing

Technology may define precision, but craftsmanship defines quality. At Infinity Truss, our factory team combines years of practical experience with engineering discipline.

From the first cut to the final weld, every truss is the result of attention to detail, teamwork, and pride in workmanship.

Our welders follow international standards such as AWS D1.2 (Structural Welding Code – Aluminum) to ensure every joint can withstand long-term stress and heavy loads. Each weld bead is visually inspected and tested using ultrasonic or dye-penetrant methods to detect microscopic flaws.

The result? A structure that’s not only strong but also beautifully finished — a hallmark of Infinity Truss products.

Rigorous Quality Control: Tested to Perform

Quality control isn’t a final step — it’s an ongoing commitment. Our factory has implemented a multi-layer QC system that tracks each product from raw material sourcing to shipment.

Key Quality Inspection Stages:

-

Incoming Material Inspection – Each aluminum batch is verified for alloy composition and mechanical strength.

-

In-Process Monitoring – Weld strength and dimensional accuracy checked in real-time.

-

Load Testing and Safety Verification – Every truss model undergoes static and dynamic load tests simulating real-world pressure.

-

Final Visual & Surface Inspection – Ensures smooth finishes, accurate connections, and assembly compatibility.

All test data is archived digitally for traceability, aligning with TÜV and ISO9001 standards.

Customization and OEM/ODM Manufacturing

As a global OEM & ODM truss manufacturer, Infinity Truss provides customized production solutions to meet different client demands — whether for distributors, rental companies, or event contractors.

We offer:

-

OEM Branding: Logos and color finishes tailored for your company identity.

-

ODM Solutions: Unique product designs engineered from concept to completion.

-

Flexible Order Volumes: From small-batch prototypes to bulk export production.

Our engineering team collaborates directly with clients via CAD drawings and 3D previews, ensuring every custom truss system integrates perfectly with their vision.

Global Export and Logistics Support

Infinity Truss products reach over 40 countries and regions, including the United States, UK, Netherlands, Malaysia, Thailand, and Colombia.

We manage logistics through trusted international freight partners, offering both sea and air shipping options. Each truss is securely packed using custom-fit foam and reinforced wooden crates to prevent damage during transit.

We also provide detailed assembly manuals, test reports, and certificates with every shipment — ensuring customers receive not only a product but also the full confidence to deploy it safely on-site.

The Future of Truss Manufacturing

As sustainability becomes central to modern industry, Infinity Truss is evolving its factory operations with environmentally responsible practices:

-

Aluminum waste recycling programs.

-

Energy-efficient welding and cutting systems.

-

Digital process control to reduce material waste.

-

Employee training for green manufacturing awareness.

Through innovation and responsibility, we aim to lead the next era of precision truss manufacturing — one that balances performance, aesthetics, and sustainability.

The content above is provided by Infitruss for informational purposes. Unauthorized reproduction is prohibited. See our full disclaimer here