The Strength Behind Every Stage: How Infitruss Uses High-Strength Aluminum (6061-T6) to Redefine Stage Truss Safety and Performance

Introduction: The Foundation of Every Great Event

Behind every unforgettable concert, elegant wedding, or dazzling live performance lies one critical structure — the stage truss. These aluminum frameworks are the unsung heroes that hold lights, sound systems, LED screens, curtains, and even entire roof structures safely above performers and audiences.

At Infinity Truss & Stage Co., Limited, we believe that a reliable truss system is not just about structure — it’s about safety, aesthetics, and trust. Founded in 2010 and based in Foshan, China, Infitruss has become one of the most recognized manufacturers of custom aluminum stage trusses for weddings, concerts, exhibitions, and large-scale events across 40+ countries.

This blog takes a deep dive into the material and engineering innovations that make our trusses different — from high-strength 6061-T6 aluminum alloy to advanced surface finishing and precision load testing — proving why InfiTruss stands as a trusted global supplier in the event structure industry.

The Core of Innovation: Why 6061-T6 Aluminum Alloy Matters

When it comes to stage trusses, material selection defines everything — from safety and lifespan to installation efficiency. Infinity Truss exclusively adopts aerospace-grade 6061-T6 aluminum alloy, recognized worldwide as the international standard for high-strength truss production.

Properties of 6061-T6 Aluminum

6061-T6 aluminum is celebrated for its exceptional mechanical strength, tensile resistance, and corrosion resistance. It’s heat-treated and tempered to reach optimal hardness, ensuring the truss maintains both strength and flexibility under heavy loads.

Key properties include:

1.Tensile strength: up to 310 MPa

2.Yield strength: around 276 MPa

3. Elongation: 8–10% (excellent flexibility to resist cracking)

4. Density: only 2.7 g/cm³ — roughly one-third the weight of steel

This combination of strength and lightness is precisely why 6061-T6 is widely used in aerospace, marine engineering, and structural frameworks — and why InfiTruss has chosen it as our standard material.

Lightweight Design, Heavy-Duty Strength

The Power of Lightweight Engineering

A key advantage of aluminum trusses lies in their weight-to-strength ratio. Compared to traditional steel frameworks, aluminum trusses are 30–40% lighter, making them much easier to transport, assemble, and disassemble without sacrificing load capacity.

For stage setup teams, this means:

1. Faster and safer installation on-site

2. Reduced transportation costs

3. Easier handling during setup and teardown

4. Better adaptability for indoor and outdoor environments

At InfiTruss, every truss is precision-engineered to achieve optimal strength with minimal weight, enabling high load capacities even with large spans.

Corrosion Resistance and Surface Treatment Technology

Beyond Strength — The Beauty of Durability

Outdoor events often expose trusses to rain, humidity, and direct sunlight. To ensure longevity and aesthetics, Infinity Truss applies advanced surface treatment technologies that protect every truss against corrosion and oxidation.

Our main treatments include:

1. Anodizing: Creates a dense, corrosion-resistant oxide film that enhances both durability and appearance.

2. Electrophoresis (E-Coating): Adds uniform, long-lasting color layers with strong adhesion and UV resistance.

3. Powder Coating: Offers excellent impact resistance, weatherproofing, and custom color finishes for branding or decoration.

These treatments not only protect the metal surface but also improve the overall visual appeal, making Infinity Truss structures suitable for weddings, exhibitions, and corporate events that require both functionality and elegance.

Precision Engineering: The Structure Behind Safety

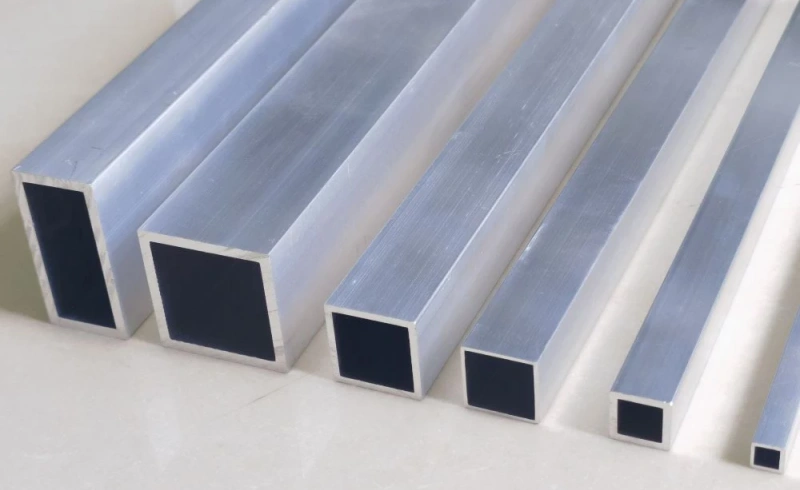

Standard and Custom Pipe Dimensions

InfiTruss carefully selects and produces aluminum pipes with optimal diameters and wall thickness for different structural needs.

Common specifications include:

1. Main tubes: 50x3mm, 50x4mm

2. Sub tubes: 50x2mm, 30x2mm, 25x2mm, 20x2mm, 12x2mm

This structural diversity allows for flexibility across various truss configurations — whether it’s a 4-meter circular wedding truss, a 40ft stage roof, or a full-scale concert system.

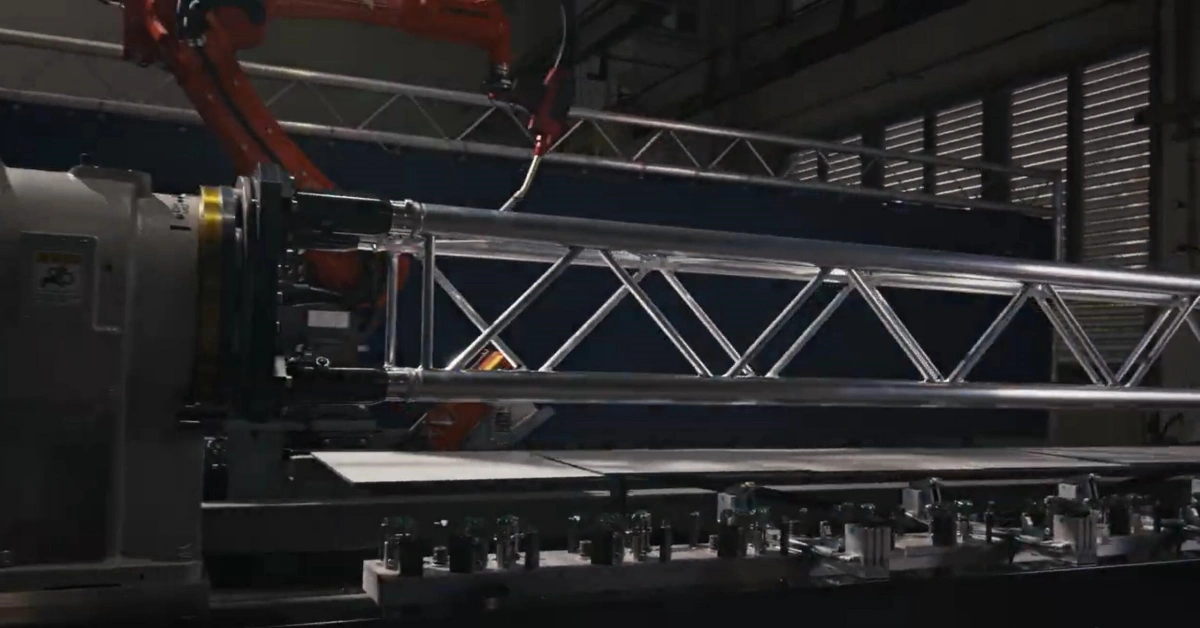

CNC Precision & Welding Excellence

All Infitruss products are manufactured using CNC machining and TIG welding technology, ensuring seamless joints and consistent accuracy.

Every weld is done by certified technicians with 10+ years of experience, guaranteeing both structural integrity and aesthetic quality.

Rigorous Load Testing & TUV Certification

Safety Is Not Negotiable

Each truss system undergoes strict load capacity testing and TUV-certified structural verification to meet international standards.

Before leaving the factory, every truss is tested under real-world conditions to ensure:

1. Consistent load-bearing performance

2. Resistance to bending, twisting, and fatigue

3. Safety under dynamic conditions (lighting, wind load, suspended LED screens)

4. InfiTruss follows the principle:

“Safety is our lifeline, innovation is our advantage, and service is our core.”

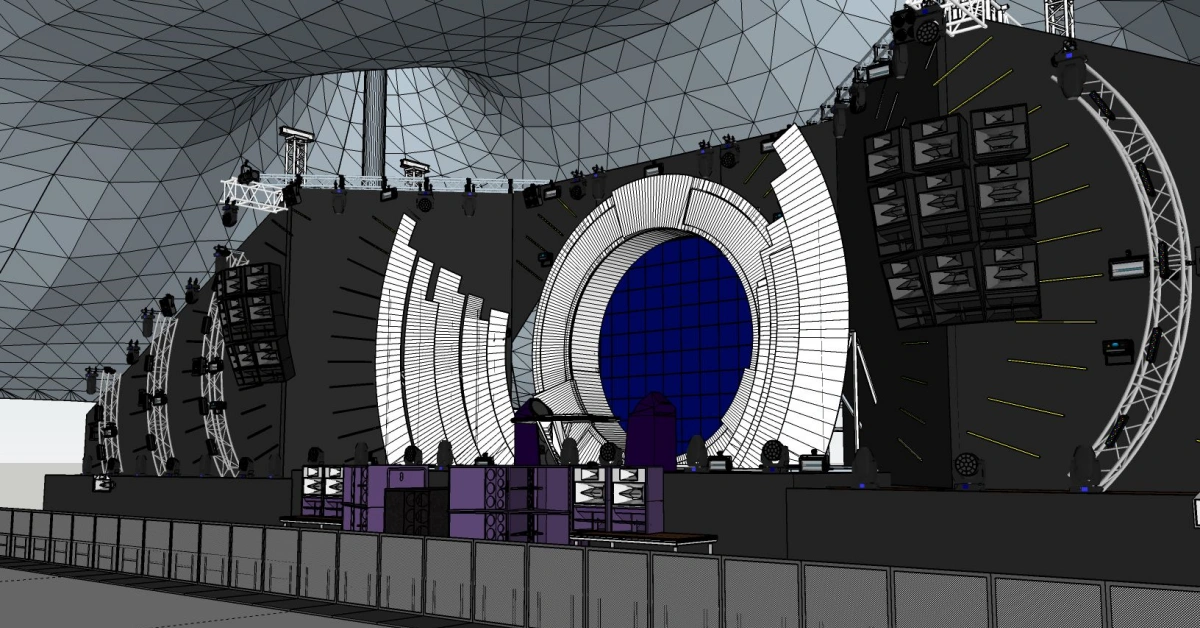

Customization and Modular Design Flexibility

From Concept to Reality

InfiTruss provides fully customized stage truss solutions for:

1. Weddings & event decoration

2. Concerts & live performances

3. Trade shows & exhibitions

4. Corporate & festival stages

We support both ground-support (pillar) installations and hanging systems, adapting to indoor and outdoor environments.

Every design is built using advanced CAD modeling to ensure compatibility, stability, and elegance.

Custom Accessories and Square Tubes

In addition to standard round trusses, Infitruss also designs and fabricates custom square tubes, corner blocks, and connecting accessories, ensuring perfect integration across different stage systems.

Why Aluminum Trusses Outperform Steel Structures

| Feature | Aluminum Truss | Steel Structure |

|---|---|---|

| Weight | Light (30–40% less) | Heavy |

| Corrosion Resistance | Excellent (especially after anodizing) | Prone to rust |

| Maintenance | Low | High |

| Installation | Fast and easy | Requires heavy tools |

| Aesthetics | Sleek & modern | Industrial look |

| Load Capacity | High relative to weight | High but heavy |

This comparison highlights why aluminum trusses have become the global standard for modern events and stage systems.

Infitruss Manufacturing Excellence

Over a Decade of Experience

Since 2010, InfiTruss has been dedicated to researching, designing, and manufacturing aluminum trusses that deliver unmatched reliability and safety.

With over a decade of production expertise and 40+ export markets, our products are trusted by clients in:

the United States, United Kingdom, Netherlands, Malaysia, Singapore, India, Australia, and more.

Quality Control System

Every stage of production — from raw material inspection to final welding and polishing — is performed under a strict quality management system.

1. Each batch of aluminum is checked for alloy consistency.

2. Welding seams are visually and mechanically inspected.

3. Load capacity tests are documented and certified.

The Role of InfiTruss in the Global Event Industry

Infitruss structures have been used in weddings, concerts, trade fairs, music festivals, and corporate celebrations worldwide.

Our lightweight yet durable systems help event organizers create unforgettable atmospheres — combining beauty, functionality, and safety.

We provide:

1. Quick delivery (within 5 business days for standard models)

2. Factory-direct pricing to reduce procurement costs

3. OEM & ODM customization for international clients

A Sustainable Approach to Stage Design

Aluminum is 100% recyclable, making it an environmentally friendly choice for modern event structures.

Infinity Truss ensures that all manufacturing processes minimize waste and energy consumption — supporting a greener future for the event industry.

Customer Trust and Global Partnerships

Infitruss has earned long-term partnerships with event planners, rental companies, and production houses worldwide.

Our clients value:

1. Reliable performance under pressure

2. Beautiful finishes suitable for luxury weddings

3. Expert engineering support for custom projects

4. Consistent quality and after-sales service

5. We don’t just sell trusses — we build trust, safety, and reputation.

Conclusion: The Future of Stage Truss Technology

As the event industry continues to evolve toward larger, more complex, and visually stunning productions, the demand for high-strength, lightweight, and corrosion-resistant aluminum trusses will only grow.

The content above is provided by Infitruss for informational purposes. Unauthorized reproduction is prohibited. See our full disclaimer here